【產(chǎn)品用途】

集團(tuán)生產(chǎn)的J41H、J41Y 型高溫高壓截止閥適用于公稱壓力150LB~2500LB�,工作溫度為570℃的石油、化工 ����、水力 、火力電站各種系統(tǒng)的管路中�,切斷或接通管路介質(zhì)�。

【產(chǎn)品特點(diǎn)】

1、閥門中腔采用壓力自緊式密封結(jié)構(gòu)�,密封性能越好。支管兩端為焊接結(jié)構(gòu)�����。焊接坡口可按標(biāo)準(zhǔn)或用戶要求配接

2、閥瓣���、閥座的密封面采用司太立鈷基硬質(zhì)合金堆焊而成���,耐磨、耐高溫����,抗擦傷性能好、使用壽命長

3����、閥桿經(jīng)調(diào)質(zhì)和表面氮化處理,有良好的搞腐蝕性和抗擦傷性�。

4、閥蓋填料函深度合理��,填料加緩蝕劑���,密封可靠

【執(zhí)行標(biāo)準(zhǔn)】

設(shè)計(jì)標(biāo)準(zhǔn):ASME B16.34

結(jié)構(gòu)長度:SME B16.10

試驗(yàn)與檢驗(yàn):API 598

壓力-溫度:ASME B16.34

產(chǎn)品標(biāo)識:ASME B16.34

【性能參數(shù)】

|

公稱壓力

|

150LB

|

300LB

|

600LB

|

900LB

|

1500LB

|

2500LB

|

|

工作壓力(MPa)

|

2.0

|

5.0

|

10.0

|

15.0

|

25.0

|

45.0

|

|

適用溫度(℃)

|

≤570

|

≤570

|

≤570

|

≤570

|

≤570

|

≤570

|

|

適用介質(zhì)

|

蒸汽等高溫高壓價值

|

|

材料

|

閥體�����、閥蓋

|

鉻鉬釩鋼

|

|

閥瓣

|

鉻鉬釩鋼+堆焊硬質(zhì)合金

|

|

閥座

|

鉻鉬釩鋼+堆焊硬質(zhì)合金

|

|

閥桿

|

鉻鉬釩鋼

|

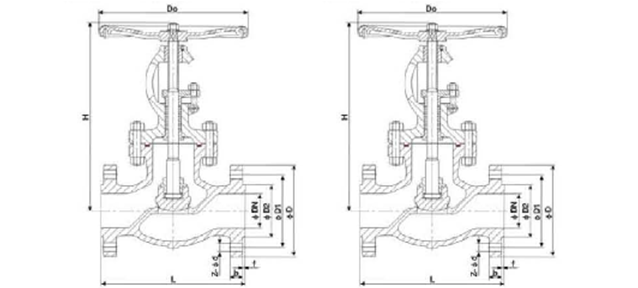

【主要外形和連接尺寸】

|

DN

|

L

|

D

|

D1

|

D2

|

f

|

b

|

z-Φd

|

H

|

D0

|

|

150(LB)

|

|

DN15

|

108

|

90

|

60.3

|

35

|

2

|

8

|

4-Φ16

|

235

|

125

|

|

DN20

|

117

|

100

|

70

|

43

|

2

|

9

|

4-Φ16

|

241

|

125

|

|

DN25

|

127

|

110

|

79.4

|

51

|

2

|

9.6

|

4-Φ16

|

242

|

125

|

|

DN32

|

140

|

115

|

89

|

63.5

|

2

|

11.2

|

4-Φ16

|

280

|

160

|

|

DN40

|

165

|

125

|

98.4

|

73

|

2

|

12.7

|

4-Φ16

|

315

|

160

|

|

DN50

|

203

|

150

|

120.7

|

92

|

2

|

14.3

|

4-Φ19

|

350

|

200

|

|

DN65

|

216

|

180

|

139.7

|

105

|

2

|

15.9

|

4-Φ19

|

370

|

200

|

|

DN80

|

241

|

190

|

152.4

|

127

|

2

|

17.5

|

4-Φ19

|

385

|

250

|

|

DN100

|

292

|

230

|

190.5

|

157.2

|

2

|

22.3

|

8-Φ19

|

454

|

250

|

|

DN125

|

356

|

255

|

216

|

185.7

|

2

|

22.3

|

8-Φ22.5

|

472

|

355

|

|

DN150

|

406

|

280

|

241.5

|

216

|

2

|

23.9

|

8-Φ22.5

|

541

|

355

|

|

DN200

|

495

|

345

|

298.5

|

270

|

2

|

27

|

8-Φ22.5

|

590

|

450

|

|

DN250

|

622

|

405

|

362

|

324

|

2

|

28.6

|

12-Φ25.5

|

780

|

450

|

|

DN300

|

698

|

485

|

438

|

381

|

2

|

30.2

|

12-Φ25.5

|

870

|

500

|

|

DN350

|

787

|

535

|

476.3

|

413

|

2

|

33.4

|

12-Φ28.5

|

900

|

600

|

|

DN400

|

914

|

595

|

540

|

470

|

2

|

35

|

16-Φ28.5

|

1250

|

600

|

|

DN450

|

-

|

635

|

578

|

533.4

|

2

|

38.1

|

16-Φ32

|

-

|

610

|

|

300(LB)

|

|

DN15

|

152

|

95

|

66.7

|

35

|

2

|

12.7

|

4-Φ16

|

241

|

125

|

|

DN20

|

178

|

115

|

82.6

|

43

|

2

|

14.3

|

4-Φ19

|

241

|

125

|

|

DN25

|

203

|

125

|

89

|

50.8

|

2

|

15.9

|

4-Φ19

|

283

|

160

|

|

DN32

|

216

|

135

|

98.5

|

63.5

|

2

|

17.5

|

4-Φ19

|

320

|

200

|

|

DN40

|

229

|

155

|

114.3

|

73

|

2

|

19.1

|

4-Φ22.5

|

322

|

200

|

|

DN50

|

267

|

165

|

127

|

92.1

|

2

|

20.7

|

8-Φ19

|

345

|

200

|

|

DN65

|

292

|

190

|

149.2

|

104.8

|

2

|

23.9

|

8-Φ22.5

|

377

|

250

|

|

DN80

|

318

|

210

|

168.3

|

127

|

2

|

27

|

8-Φ22.5

|

464

|

280

|

|

DN100

|

356

|

255

|

200

|

157.2

|

2

|

30.2

|

8-Φ22.5

|

490

|

355

|

|

DN125

|

400

|

280

|

235

|

185.7

|

2

|

33.4

|

8-Φ22.5

|

614

|

400

|

|

DN150

|

444

|

320

|

270

|

216

|

2

|

35

|

12-Φ22.5

|

700

|

450

|

|

DN200

|

559

|

380

|

330.2

|

270

|

2

|

39.7

|

12-Φ25.5

|

777

|

500

|

|

DN250

|

622

|

445

|

387.4

|

323.8

|

2

|

46.1

|

16-Φ28.5

|

935

|

550

|

|

DN300

|

711

|

520

|

450.8

|

381

|

2

|

49.3

|

16-Φ32

|

997

|

600

|

|

DN350

|

762

|

585

|

514.4

|

412.8

|

2

|

52.4

|

20-Φ32

|

1058

|

650

|

|

DN400

|

864

|

650

|

571.5

|

470

|

2

|

55.6

|

20-Φ35

|

1320

|

700

|

|

600(LB)

|

|

DN15

|

165

|

95

|

66.7

|

35

|

7

|

14.3

|

4-Φ16

|

245

|

156

|

|

DN20

|

190

|

115

|

82.6

|

43

|

7

|

15.9

|

4-Φ19

|

245

|

161

|

|

DN25

|

216

|

125

|

89

|

50.8

|

7

|

17.5

|

4-Φ19

|

290

|

187

|

|

DN32

|

229

|

135

|

98.4

|

63.5

|

7

|

20.7

|

4-Φ19

|

325

|

214

|

|

DN40

|

241

|

155

|

114.3

|

73

|

7

|

22.3

|

4-Φ22.5

|

330

|

252

|

|

DN50

|

292

|

165

|

127

|

92.1

|

7

|

25.4

|

8-Φ19

|

345

|

430

|

|

DN65

|

330

|

190

|

149.2

|

104.8

|

7

|

28.6

|

8-Φ22.5

|

365

|

480

|

|

DN80

|

356

|

210

|

168.3

|

127

|

7

|

31.8

|

8-Φ22.5

|

465

|

530

|

|

DN100

|

432

|

275

|

216

|

157

|

7

|

38.1

|

8-Φ25.5

|

520

|

650

|

|

DN125

|

508

|

330

|

266.7

|

185.7

|

7

|

44.5

|

8-Φ28.5

|

635

|

750

|

|

DN150

|

559

|

355

|

292.1

|

216

|

7

|

47.7

|

12-Φ28.5

|

763

|

850

|

|

DN200

|

660

|

420

|

349.2

|

270

|

7

|

55.6

|

12-Φ32

|

845

|

1050

|

|

DN250

|

787

|

510

|

431.8

|

323.8

|

7

|

63.5

|

16-Φ35

|

930

|

1257

|

|

DN300

|

838

|

560

|

489

|

381

|

7

|

66.7

|

20-Φ35

|

1010

|

1468

|

|

DN350

|

889

|

605

|

527

|

412.8

|

7

|

69.9

|

20-Φ38

|

1090

|

1623

|

|

DN400

|

991

|

685

|

603.2

|

470

|

7

|

76.2

|

20-Φ41

|

1140

|

1816

|

|

900(LB)

|

|

DN50

|

368

|

215

|

165.1

|

92.1

|

7

|

38.1

|

8-Φ25.5

|

430

|

320

|

|

DN65

|

419

|

245

|

190.5

|

104.8

|

7

|

41.3

|

8-Φ28.5

|

530

|

320

|

|

DN80

|

381

|

265

|

190.5

|

127

|

7

|

38.1

|

8-Φ28.5

|

580

|

360

|

|

DN100

|

457

|

290

|

235

|

157.2

|

7

|

44.5

|

8-Φ32

|

690

|

450

|

|

DN125

|

559

|

350

|

279.4

|

185.7

|

7

|

50.8

|

8-Φ35

|

780

|

560

|

|

DN150

|

610

|

380

|

317.5

|

216

|

7

|

55.6

|

12-Φ32

|

890

|

630

|

|

DN200

|

737

|

470

|

393.7

|

270

|

7

|

63.5

|

12-Φ38

|

1240

|

720

|

|

DN250

|

838

|

545

|

470

|

323.8

|

7

|

69.9

|

16-Φ38

|

1651

|

760

|

|

1500(LB)

|

|

DN65

|

419

|

245

|

190.5

|

104.8

|

7

|

41.6

|

8-Φ28.5

|

530

|

400

|

|

DN80

|

470

|

265

|

203.2

|

127

|

7

|

47.7

|

8-Φ32

|

590

|

450

|

|

DN100

|

546

|

310

|

241.3

|

157.2

|

7

|

54

|

8-Φ35

|

710

|

500

|

|

DN125

|

673

|

375

|

292.1

|

185.7

|

7

|

73.1

|

8-Φ41

|

780

|

560

|

|

DN150

|

705

|

395

|

317.5

|

215.9

|

7

|

82.6

|

12-Φ38

|

904

|

630

|

|

DN200

|

832

|

485

|

393.7

|

270

|

7

|

92.1

|

12-Φ45

|

1140

|

560

|

|

2500(LB)

|

|

DN65

|

508

|

265

|

196.8

|

104.8

|

7

|

57.2

|

8-Φ32

|

740

|

400

|

|

DN80

|

578

|

305

|

228.6

|

127

|

7

|

66.7

|

8-Φ35

|

780

|

450

|

|

DN100

|

637

|

355

|

273

|

157.2

|

7

|

76.2

|

8-Φ41

|

860

|

560

|

|

DN125

|

794

|

420

|

323.8

|

185.7

|

7

|

92.1

|

8-Φ48

|

930

|

630

|

|

DN150

|

914

|

485

|

368.3

|

216

|

7

|

108

|

8-Φ54

|

1070

|

560

|

|

DN200

|

1022

|

550

|

438.2

|

270

|

7

|

127

|

12-Φ54

|

1180

|

630

|

【結(jié)構(gòu)圖片】